Lab 7: Volumetric Analysis and Intercomparison

By: Jack Radenz

Introduction:

In order to run a profitable business operation, it is vital for quarry owners to monitor the influx in resources across time within the mine. Resources commonly are being hauled in and out within mines creating a challenge to monitor the gain or deficit of resources. This is called volumetric change calculation/estimation. This process can be one of the most expensive services that a mine owner will pay for. High 2D and 3D locational accuracy needs to be achieved in order to deliver an accuracy estimation. This service has commonly used airborne Lidar or total stations to receive their results. However, as of late the capability to use UAS to monitor volumetric change has been examined. Using UAS to monitor volumetric change is a much safer and time efficient practice, which benefits both the mine owner and the service provider. Below we test the suitability of using UAS.

Study Area:

Figure 1. Study Area - La Crescent Rock Products Inc.

- La Crescent Rock Products Inc. ~ La Crescent, MN

- The site was originally covered by forest. In the late 1980's the land cover was used for agricultural practices, however in the early to late 2000's the land was covered to a quarry for stockpiling rocks and minerals. Blasts are frequent throughout the quarry to modify the landscape.

- Total area covered ~ 80 acres

Volumetric Calculation:

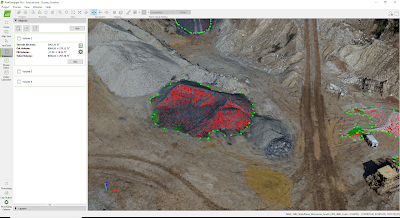

Pix4D:

- Digitize individual stockpiles and compute volume

Figure 2. Stockpile 1 Pix4D

Figure 3. Stockpile 2 Pix4D

Figure 4. Stockpile 3 Pix4D

ArcMap:

- Export stockpiles from Pix4D into ArcMap as shapefiles

- Load October flight DSM

- Extract by Mask (October DSM by stockpile shapefiles)

- Individual DSM stockpiles are delievered

Figure 5. DSM stockpiles

Figure 6. Calculating DSM volume

Figure 7. TIN stockpiles

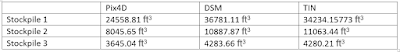

Results:

Figure 8. Volume results using each calculation platform

- Pix4D had the smallest volume estimations

- DSM had the largest volume estimations

Conclusions:

In my opinion, the Pix4D volumetric estimation is the most accurate between the 3 methods. I believe this to be true because Pix4D had a very large number of points within the point cloud compared to reference points with the TIN and DSM outputs. Pix4D doesn't assume a flat surface, therefore the volumetric measurement tool is able to detect the crevices and depressions within the stockpiles. However, the DSM is built with a flat surface (pixels) as well as the TIN (polygons). The TIN output connects a much smaller set of points (compared to the Pix 4D output) of equal elevation with polygons. Therefore, that allows the the large inaccuracy in estimation of volume.

- Therefore, 24,558.81 / 397 ~ 62 cubic feet

- For every 62 cubic feet of material there is 1 cubic foot of error.